High Impact Polystyrene Frame Mouldings

High Impact Polystyrene Frame Mouldings Specification

- Feature

- High impact resistance, lightweight, moisture resistant, termite proof

- Dimension (L*W*H)

- Customizable; typically 6mm-40mm width, Length up to 3 meters, Height 10mm-40mm

- Surface Treatment

- Smooth, glossy or matte finish

- Processing

- Extrusion

- Technique

- Hot extrusion molding

- Application

- Photo frames, mirror frames, artwork frames, decorative moulding

- Type

- Frame mouldings

- Material

- High Impact Polystyrene (HIPS)

- Shaping Mode

- Extrusion Mould

- Weight

- Approx. 250-500g/m depending on profile

- Color

- Available in white, black, wood finish, gold, silver, and customized colors

- Density

- 1.05 g/cm³

- Environmental Compliance

- RoHS and REACH Compliant

- Packaging

- Shrink Wrapped / Carton Box

- Installation Method

- Nailing, Gluing, Screwing

- UV Resistance

- Optional UV-resistant coating

- Fire Resistance

- Self-extinguishing

- Length Available

- Standard and customized (up to 3 meters)

- Water Absorption

- <0.2%

- Hardness

- Shore D 70-80

About High Impact Polystyrene Frame Mouldings

| I Deal In | New |

| Packaging Size | Normal |

| Finishing | Smooth |

| Material | High Impact Polystyrene |

| Color | Customize |

| Usage/Application | Frame Moulding |

Features:

Steel body

Many sizes and fixture available

Cost effective rates

Exceptional Strength and Safety

Our HIPS frame mouldings combine hardiness (Shore D 70-80) with a lightweight build, making them perfect for both residential and commercial applications. Their self-extinguishing properties enhance safety, providing peace of mind for projects where fire resistance is critical. With a density of 1.05 g/cm, each piece resists everyday impacts and moisture infiltration.

Tailored to Your Needs

Available lengths can be customized up to 3 meters, while width and height options accommodate a variety of framing needs. Whether you require a slim, modern profile or a stately decorative moulding, our extrusion process and style choices ensure the perfect fit every time. Surface treatment options in gloss or matte finishes add the ideal touch for any dcor.

Eco-Conscious and Built to Last

Committed to sustainability, our frame mouldings comply with RoHS and REACH standards, minimizing environmental impact. Optional UV-resistant coatings help maintain vibrant colors and structural integrity over time, especially in sunlit environments. Low water absorption (<0.2%) keeps frames looking new, even in humid settings.

FAQs of High Impact Polystyrene Frame Mouldings:

Q: How are the HIPS frame mouldings installed?

A: These mouldings can be easily installed using nails, glue, or screws, making them suitable for professional decorators and DIY enthusiasts alike. Instructions are included to ensure a secure and lasting fit to your chosen surface.Q: What applications are these frame mouldings best suited for?

A: Our HIPS frame mouldings are perfect for photo frames, mirror frames, artwork frames, and various decorative mouldings. Their durable, high-impact design is suitable for both commercial and residential settings.Q: When is a UV-resistant coating recommended for these mouldings?

A: A UV-resistant coating is suggested for mouldings exposed to direct sunlight, such as those installed near windows or in outdoor-facing areas. This option helps preserve color vibrancy and material integrity over time.Q: Where can these mouldings be supplied or delivered?

A: We are a trusted dealer, distributor, exporter, supplier, trader, and wholesaler based in India, supplying these mouldings locally and for export as required.Q: What is the process for customizing the dimensions or colors of my order?

A: You may specify your preferred length (up to 3 meters), width, height, and color. Our team will work with you from design to extrusion, ensuring your custom specifications are met before delivery.Q: How do these mouldings benefit from their self-extinguishing and moisture-resistant properties?

A: The self-extinguishing nature enhances fire safety, while low water absorption (<0.2%) ensures that the mouldings remain stable and undamaged in humid environments, making them suitable for a wide range of installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mouldings Category

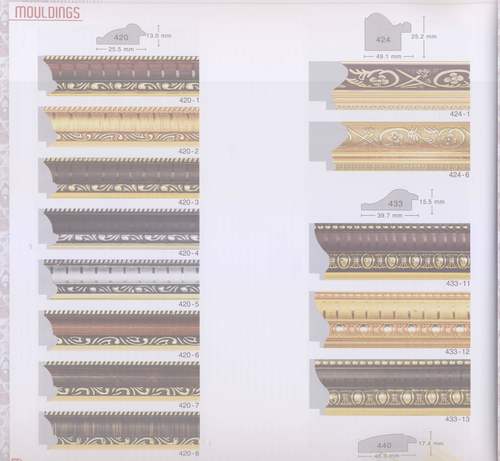

Solid Durable Frame Mouldings

Weight : Variable based on dimensions

Color : Brown White Golden

Surface Treatment : Lacquered Painted

Dimension (L*W*H) : Variable dimensions as shown in the image

Shaping Mode : Other, Extruded Profile

Feature : Durable Solid Construction Decorative Patterns

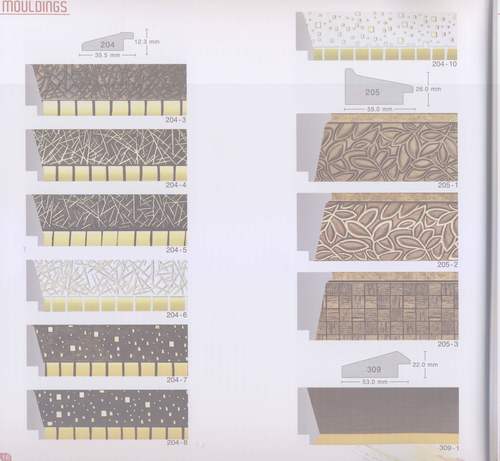

Robust Designer High Impact Polystyrene Photo Frame Mouldings

Weight : Varies by design typically lightweight

Color : Various (e.g. brown gold silver textured finishes based on image)

Surface Treatment : Textured polished or coated

Dimension (L*W*H) : Variable dimensions as per designs in image (e.g. 30mm x 10mm x 20mm)

Shaping Mode : Moulding, Other

Feature : High impact resistance durable lightweight design

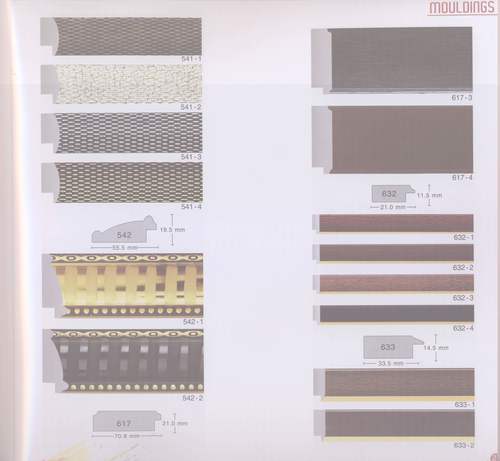

Solid Multicolor Photo Frame Mouldings

Weight : Lightweight

Color : Multicolor

Surface Treatment : Multicolor print and textured finish

Dimension (L*W*H) : Varied (Based on designs shown)

Shaping Mode : Other, Extrusion moulding

Feature : Solid construction Multicolor finishing Decorative design

Attractive Latest Design Frame Mouldings

Weight : Varies with material, typically 300g 800g per meter

Color : Multiple choices Silver, Gold, Black, White, Woodgrain, Custom colors

Surface Treatment : Laminated, polished, colored, matte/glossy options

Dimension (L*W*H) : Customizable, standard sizes available (e.g., 1 x 2.5 x variable length)

Shaping Mode : Other, Custom moulding, extrusion

Feature : Attractive design, durable, lightweight, easy installation