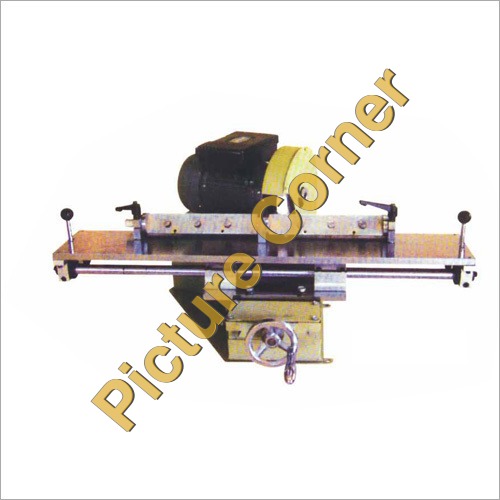

Frame Pitch Machine

About Frame Pitch Machine

| Material | Mild Steel |

| Number Of Shaft | 3 |

| Hole Diameter | 0-25 mm |

| Functions | Threading,Drilling,Tapping |

| Size | All |

| Voltage | 220v |

| Working Stroke | Pitch Machine |

| Max Hole Diameter | <50 mm |

| Automation Grade | Semi-Automatic,Automatic |

Advanced Automation for Textile Efficiency

Our Frame Pitch Machine brings automation to your textile production, greatly reducing manual intervention. With its electric power source and robust mild steel construction, it ensures long-term reliability and minimal maintenance, saving both time and resources while enhancing overall productivity.

Superior Build and Paint-Coated Finish

Designed for durability, the machine features premium mild steel with a high-quality industrial paint coat. This not only provides aesthetic appeal but also offers superior resistance to wear, corrosion, and harsh factory conditions commonly found in textile manufacturing environments.

FAQs of Frame Pitch Machine:

Q: How does the Frame Pitch Machine improve textile production processes?

A: The automatic Frame Pitch Machine accelerates and standardizes the frame pitching process, increasing production accuracy and reducing labor costs for textile manufacturers.Q: What materials are used in the construction of this machine?

A: The machine is made from robust mild steel, which is known for its strength and longevity, ensuring it withstands high-volume textile production environments.Q: When should I consider using the Frame Pitch Machine in my textile unit?

A: Investing in the Frame Pitch Machine is ideal when aiming to automate your frame pitching operations, improve precision, and achieve higher throughput in your textile production line.Q: Where is the Frame Pitch Machine available for purchase or supply?

A: The Frame Pitch Machine can be sourced from reputable dealers, distributors, exporters, suppliers, traders, and wholesalers throughout India, ensuring convenient access for textile businesses nationwide.Q: What is the typical process for installing this machine in a textile factory?

A: Installation typically involves setting up the machine at the desired location, connecting to the electric power source, and calibrating according to specific frame requirements, often facilitated by the suppliers technical team.Q: How is the surface of the Frame Pitch Machine protected against industrial conditions?

A: Its surface is treated with a high-quality industrial paint coating, offering enhanced resistance to corrosion, wear, and the demanding textile factory environment.Q: What benefits does the Frame Pitch Machine offer over manual frame pitching methods?

A: It provides improved consistency, greater speed, and reduced physical strain on workers, resulting in lower operational costs and enhanced output quality for textile businesses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email