Light Weight Durable Picture Mouldings

Light Weight Durable Picture Mouldings Specification

- Dimension (L*W*H)

- Customizable as per requirement

- Technique

- Extruded and Moulded

- Application

- Framing Pictures, Mirrors, Artwork

- Feature

- Light Weight, Durable, Moisture Resistant, Eco-Friendly

- Surface Treatment

- Laminated, Polished, Painted

- Processing

- Precision Cutting, Profiling

- Type

- Picture Moulding

- Material

- PVC Polymer, UPVC

- Shaping Mode

- Moulding

- Weight

- Light Weight (Varies per dimensions)

- Color

- Available in Multiple Colors & Finishes

About Light Weight Durable Picture Mouldings

| I Deal In | New |

| Packaging Size | Normal |

| Finishing | Smooth |

| Material | High Impact Polystyrene |

| Color | Customize |

| Usage/Application | Frame Moulding |

Features:

Steel body

Many sizes and fixture available

Cost effective rates

Versatile Design and Custom Options

Choose from flat, decorative, beveled, or custom profiles to perfectly complement your framing needs. Standard lengths of 8ft and 10ft are readily available, with the flexibility to order custom dimensions and colors for large projects or unique spaces. Precision cutting and profiling ensure a high-quality finish, no matter the specification.

Reliability for Demanding Environments

These mouldings offer robust durability, resisting common household chemicals, moisture, and UV exposure to ensure lasting performance indoors. Optional fire retardancy provides added safety upon request. Maintenance is minimalsimply wipe clean with a damp cloth to retain their pristine look.

Hassle-Free Installation and Fast Fulfillment

Designed for easy installation using everyday tools, these picture mouldings streamline your projects. With a lead time of 2-4 weeks for bulk orders and customizable minimum order quantities, sourcing is convenient and tailored to your requirements. Secure packaging in shrink-wrap and carton boxes ensures safe deliveries every time.

FAQs of Light Weight Durable Picture Mouldings:

Q: How do I install these lightweight picture mouldings?

A: Installation is straightforward and can be accomplished with common household tools. The mouldings are designed to be easy to handle and affix, making them suitable for both DIY and professional applications without the need for specialized equipment.Q: What custom options are available for length, color, and profile shape?

A: You can order standard 8ft or 10ft mouldings, or request custom lengths as needed. Additionally, a range of profilesincluding flat, beveled, decorative, or unique custom shapesis available, with multiple color and finish options to match your interior style.Q: When can I expect delivery for bulk or custom orders?

A: Bulk and custom orders typically have a lead time of 2-4 weeks. This schedule allows for precision cutting, profiling, and any special surface treatments or fire retardancy requests, ensuring your order meets all specifications.Q: Where are these mouldings suitable for installation?

A: Our mouldings are designed for indoor environments, ideal for framing pictures, mirrors, and artwork in homes, galleries, offices, and commercial spaces. Their UV resistance and moisture resistance make them resilient and long-lasting indoors.Q: What is the process for requesting fire retardant mouldings?

A: Fire retardancy is available upon request. Simply specify this requirement when placing your order, and the necessary treatments will be applied during manufacturing to ensure compliance and safety.Q: How should I maintain and clean the mouldings?

A: Maintenance is minimaljust wipe the surface clean with a damp cloth to remove dust or smudges. The chemical-resistant material ensures durability against common household cleaners.Q: What are the benefits of choosing these mouldings over traditional wood or metal frames?

A: These mouldings are lightweight for easier handling and installation, durable against moisture and chemicals, offer customizable profiles and colors, and can be made fire retardant. They are eco-friendly, comply with RoHS & REACH standards, and are shipped securely to meet your project needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mouldings Category

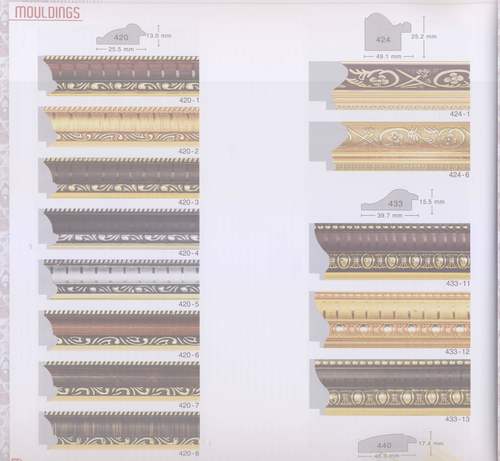

Modern Design Picture Frame Mouldings

Material : Other, Wood Plastic and Composite materials

Technique : Machine processing and hand finishing

Application : Picture Frame Mouldings

Shaping Mode : Other, Moulding

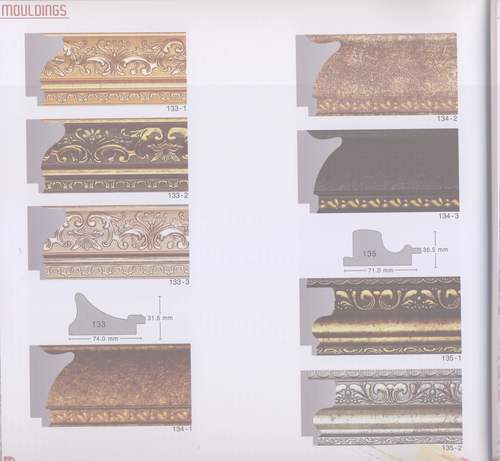

Dimension (L*W*H) : Various dimensions detailed in the image (e.g. thickness height)

Surface Treatment : Painted Gilded or Laminated

Mesmerising Look Frame Mouldings

Material : Wood or composite materials with metallic coating, Other

Technique : High precision carving and moulding

Application : Interior decoration and framing

Shaping Mode : Moulded, Other

Dimension (L*W*H) : Varied dimensions; common length approximately 12 meters

Surface Treatment : Lacquered polished and metallic coatings

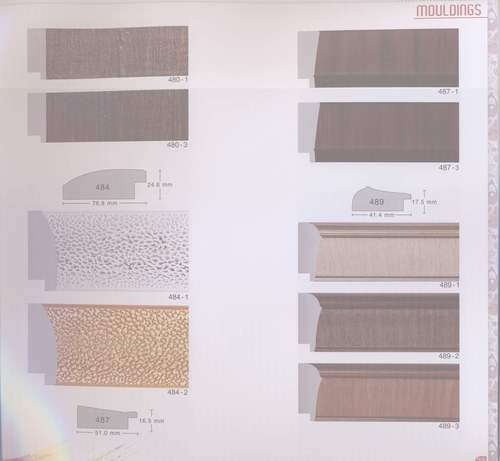

Printed Frame Mouldings For Framing Photos

Material : Other, Polystyrene/PU, wood or composite

Technique : Extrusion and digital printing

Application : Framing photos, artworks, certificates

Shaping Mode : Other, Extruded profile

Dimension (L*W*H) : Customizable as per requirement

Surface Treatment : Laminated or finished surface

High Impact Polystyrene Frame Mouldings

Material : Other, High Impact Polystyrene (HIPS)

Technique : Hot extrusion molding

Application : Photo frames, mirror frames, artwork frames, decorative moulding

Shaping Mode : Extrusion Mould

Dimension (L*W*H) : Customizable; typically 6mm40mm width, Length up to 3 meters, Height 10mm40mm

Surface Treatment : Smooth, glossy or matte finish