Glossy Polystyrene Photo Frame Mouldings

Glossy Polystyrene Photo Frame Mouldings Specification

- Surface Treatment

- Glossy Finish Coating

- Feature

- Lightweight, Durable, UV Resistant, Moisture Proof

- Technique

- Injection Moulding

- Application

- Photo Frame Mouldings, Decorative Edging

- Dimension (L*W*H)

- Available in multiple sizes, generally ranging from 1 inch to 3 inches in width; length customizable as per photo frame requirements; height approximately 20mm-40mm

- Processing

- Extrusion and precision cutting

- Type

- Polystyrene Photo Frame Moulding

- Material

- High-Quality Polystyrene

- Shaping Mode

- Extruded and Injection Moulded

- Weight

- Approx. 200-500 grams per meter

- Color

- Glossy White, Black, Silver, Custom Colors Available

- Lead Time

- Typically 5-15 days depending on order quantity

- Temperature Resistance

- Can withstand temperatures up to 80°C

- Gloss Level

- High gloss, mirror-like surface

- MOQ

- 100 meters

- Fire Rating

- Flame retardant polystyrene

- Packing

- Packed in shrink wrap or carton boxes

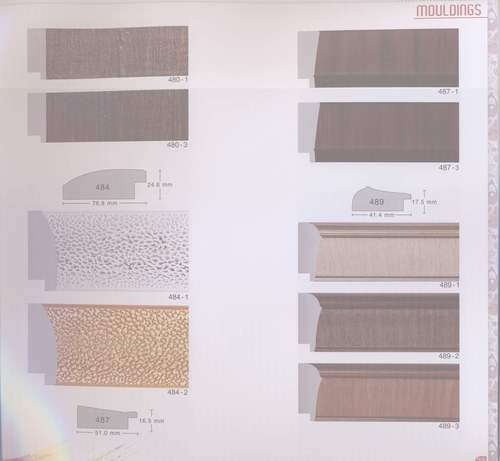

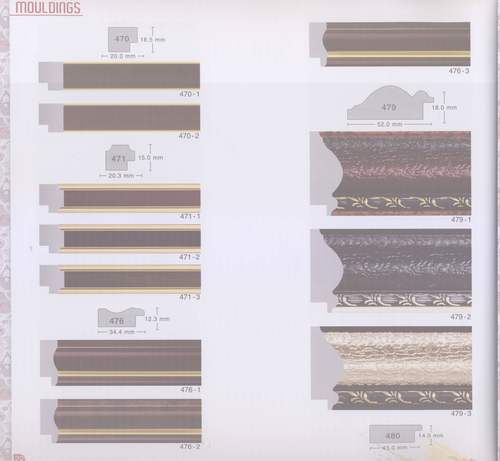

- Edge Profile

- Various classic and modern profiles (flat, rounded, ornate)

- Environmental Compliance

- RoHS and REACH compliant

- Installation

- Easy to cut and nail, suitable for DIY and commercial framing

- Maintenance

- Cleanable with damp cloth; stain resistant

- Compatibility

- Compatible with standard glass, acrylic, MDF, and art backing

About Glossy Polystyrene Photo Frame Mouldings

| I Deal In | New |

| Packaging Size | Normal |

| Finishing | Smooth |

| Material | High Impact Polystyrene |

| Color | Customize |

| Usage/Application | Frame Moulding |

Features:

Steel body

Many sizes and fixture available

Cost effective rates

Modern Design and Peak Durability

Our glossy polystyrene photo frame mouldings combine contemporary style with robust, long-lasting performance. Their high gloss finish offers a mirror-like effect, available in a range of colors from classic black and white to custom tones. This versatility ensures they complement a variety of dcor themes, while the flame retardant construction delivers peace of mind.

Effortless Installation and Versatile Application

Designed for both professional and DIY framers, these mouldings are easy to cut and nail, making them perfect for custom projects and commercial production alike. Compatible with standard framing materials like glass and MDF, they support a seamless framing process whether used for decorative edging or full photo frames.

Safe, Sustainable, and Low Maintenance

Safety and environmental responsibility are built into these mouldings, which comply with RoHS and REACH standards and are manufactured using optimized extrusion and injection moulding techniques. Their easy-to-clean, stain-resistant surface makes them a smart choice for busy, modern spaces seeking both aesthetics and practicality.

FAQs of Glossy Polystyrene Photo Frame Mouldings:

Q: How can I install these glossy polystyrene photo frame mouldings?

A: The mouldings are designed for easy installation. They can be precisely cut and securely nailed using standard tools, making them suitable for both professional framing workshops and DIY applications at home.Q: What backing materials are compatible with these mouldings?

A: These mouldings are compatible with standard glass, acrylic, MDF, and various art backings, ensuring flexibility for diverse framing requirements and artistic setups.Q: When can I expect my order to be delivered?

A: The standard lead time for these mouldings is typically 5 to 15 days, depending on your order quantity and customization requirements.Q: Where can these mouldings be used besides photo frames?

A: Apart from traditional photo frames, these mouldings are also ideal for decorative edging on mirrors, art pieces, and custom display projects, both at home and in commercial settings.Q: What is the benefit of choosing polystyrene over traditional wood mouldings?

A: Polystyrene mouldings offer the advantage of being lightweight, durable, UV-resistant, and moisture-proof. They maintain their appearance and integrity even in varying temperatures and require minimal maintenance compared to traditional materials.Q: How do I maintain the glossy finish on these mouldings?

A: Simply wipe the mouldings with a damp cloth to clean them. The stain-resistant, glossy surface ensures that dirt and marks can be removed easily, keeping frames looking pristine for longer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mouldings Category

Solid Multicolor Photo Frame Mouldings

Type : Photo Frame Mouldings

Application : Photo Frame Mouldings

Shaping Mode : Other, Extrusion moulding

Weight : Lightweight

Dimension (L*W*H) : Varied (Based on designs shown)

Processing : Machine processed

Light Weight Durable Picture Mouldings

Type : Picture Moulding

Application : Framing Pictures, Mirrors, Artwork

Shaping Mode : Other, Moulding

Weight : Light Weight (Varies per dimensions)

Dimension (L*W*H) : Customizable as per requirement

Processing : Precision Cutting, Profiling

Printed Frame Mouldings For Framing Photos

Type : Printed Frame Mouldings

Application : Framing photos, artworks, certificates

Shaping Mode : Other, Extruded profile

Weight : Varies as per dimensions

Dimension (L*W*H) : Customizable as per requirement

Processing : Printing and moulding

Fine Finish Long Life Frame Mouldings

Type : Frame Mouldings

Application : Photo Frames, Picture Frames, Decorative Frames, Doors, Windows

Shaping Mode : Extrusion Mould

Weight : Lightweight

Dimension (L*W*H) : Customizable as per requirement

Processing : Precision Machined and Finished